GTX-500

ROUND | SQUARE | RECTANGULAR

HR PIPES

Ratnakar GTX-500 HR Pipes can be manufactured up to a maximum size of 72x72 mm for square sections, 96x48 mm for rectangular sections. The thickness can vary from 1.2 mm to 4.2 mm.

Ratnakar GTX-500 HR Pipes has recently forayed into retail space under the initiative Ratnakar GTX-500 HR Pipes, providing consumers with 360 degree solutions right from the design to the fabrication stage. Adding to the product portfolio as well as catering to the changing consumer demands.

Ratnakar GTX-500 HR Pipes has multiple applications ranging from architectural, industrial, infrastructural, general engineering to power plants, solar power plants, steel industry, railways etc.

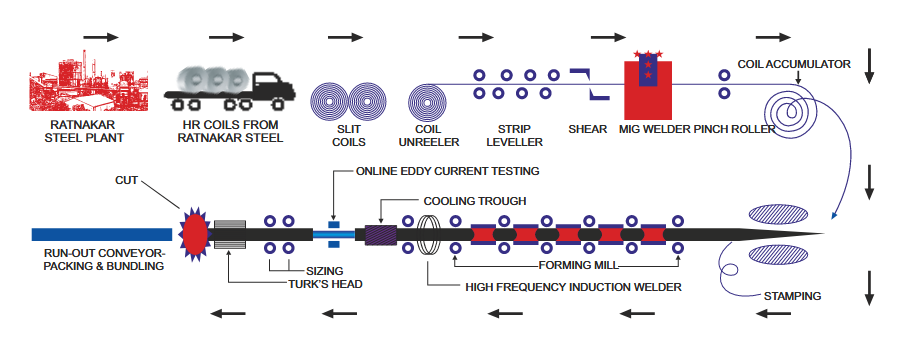

Process of GTX 500 Pipes

Quality Control

The quality of our product is controlled during the manufacturing process. It starts with slitting the strip edges, continues with speed, temperature control during the high frequency induction welding and is followed by online non destructive eddy current testing directly after welding. Off-line, drift and flattening tests are conducted. This is all within our ISO 9000, ISO 14001 & OHSAS 18001 quality management system.

Advantages of Ratnakar GTX-500 HR Pipes

The excellent distribution of material around the axis of these steel pipes for remarkable strength qualities and thus offers decisive advantages as regards to application technology.

Their higher strength to weight ratio could result in upto 30% savings in steel.

Cost Effective

By virtue of its shape, Hollow sections have high Radius of Gyration and other properties resulting in savings in Material, Transportation and Fabrication cost.

Less Surface area compared to equivalent conventional sections results in savings in Paint and Labour cost.

Corrosion Resistant

Less exposed surface area combined with superior quality raw material results very less corrosion in compare to leading brands.

Smooth uniform profiles of sections minimizes dust and moisture accumulation.

Corrosion Resistant

Less exposed surface area combined with superior quality raw material results very less corrosion in compare to leading brands.

Smooth uniform profiles of sections minimizes dust and moisture accumulation.

Concentric Strength

By virtue of its shape, Hollow sections have high Radius of Gyration resulting in higherconcentric strength.

Due to closeness of the section there will be higher torsional rigidity compared to conventional sections.

Better lateral stability and lower wind drag.

Enables weight reduction of upto 30%.

Convenience of Fabrication

Due to less weight and smoother profile, fabrication is easier.Also minimum use of gusset plates expedites the fabrication process.

Creativity

Due to higher torsional rigidity and better moment resistance on both the axis, bending of hollow section is easier compared to open sections. This gives flexibility to the architects to shape their structures and express their creativity.Smooth profile of Ratnakar GTX-500 HR Pipes enhances the aesthetic appeal of the structures.

Most suitable for usage in exposed environment.

Applications

- Shopping Malls

- Canopies/Atrium

- Glass Curtain WalFrames

- Partition Frames

- Space Frames

- Guard Rails & Staircases

- Airport TerminaBuildings

- Bridges

- Bus Stands

- Sign Supporting Structures

- Pedestrian Walkovers (Footbridge)

- Sports Galleries

- Railways Platforms / Foot Over Bridges

- Industria Sheds

- Trusses, Columns and Purlins

- MateriaStorage Racks

- Mine Roof Support Systems (cogs, props)

- Pallets

- Pipe Racks

- Conveyor Gantries, Trestles

- Drilling Rigs

- Stee& Power Plants

- Automobile Chassis

- Greenhouse Structures

- Truck & Bus Body Members

- Hoarding Structures

- Amusement Park

- Playground Equipment

- Exhibition Stalls

- Scaffolding

- Furniture

- Solar Power Plant Structures

Attributes

- Lightweight

- Flexible and easy to form shapes

- Smooth surface finish

- Appealing aesthetics

- Contemporary

- High strength

- More column free space

- Larger & thicker sections Ease of fabrication

- High strength to weight ratio

- Cost effective

- Ease of fabrication and erection

- Ease of maintenance

- Free from sharp edges

- High torsional resistance

- Minimal painting area Appealing aesthetics